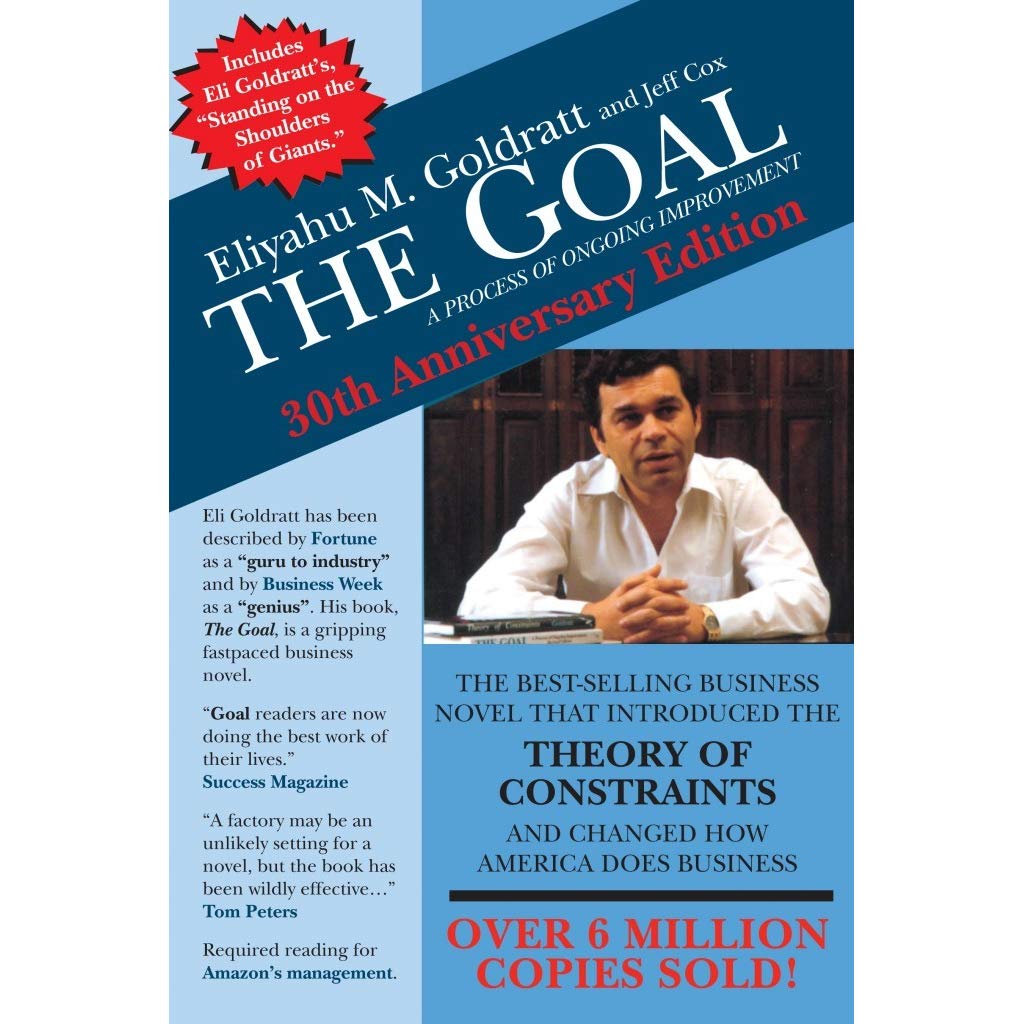

The Goal: A Process of Ongoing Improvement

von Eliyahu M. Goldratt und Jeff Cox

If you do, you basically have taken science from the ivory tower of academia and put it where it belongs, within the reach of every one of us and made it applicable to what we see around us.

productivity is the act of bringing a company closer to its goal. Every action that brings a company closer to its goal is productive. Every action that does not bring a company closer to its goal is not productive.

If the goal is to make money, then (putting it in terms Jonah might have used), an action that moves us toward making money is productive. And an action that takes away from making money is non-productive.

To make money by increasing net profit, while simultaneously increasing return on investment, and simultaneously increasing cash flow.

“They’re measurements which express the goal of making money perfectly well, but which also permit you to develop operational rules for running your plant,” he says. “There are three of them. Their names are throughput, inventory and operational expense.”

“Throughput,” he says, “is the rate at which the system generates money through sales.”

“Inventory is all the money that the system has invested in purchasing things which it intends to sell.”

“Operational expense,” he says. “Operational expense is all the money the system spends in order to turn inventory into throughput.”

“A bottleneck,” Jonah continues, “is any resource whose capacity is equal to or less than the demand placed upon it. And a non-bottleneck is any resource whose capacity is greater than the demand placed on it. Got that?”

The manufacturing industry has been shaped by two great thinkers, Henry Ford and Taiichi Ohno. Ford revolutionized mass production by introducing the flow lines. Ohno took Ford’s ideas to the next level in his TPS, a system that forced the entire industry to change its grasp of inventory from an asset to a liability.